Emerging Complex Subsea Sensor Systems Data Transmission Challenges

By: Gregory Eskridge, Technology Manager – Fiber Optics, Teledyne Oil & Gas

Deepwater systems for oil & gas production and scientific exploration are experiencing significant increases in sensor complexity and density aimed at monitoring the performance and health management of the subsea environment, therefore demanding greater bandwidth capabilities as well as high-integrity, real-time data transmission to levels never imagined a decade ago. These increased sensor demands, coupled with the growing use of large subsea power systems, are driving the need for configurable, high-reliability, electromagnetic interference (EMI)-immune networks for data acquisition and control, often with a 30-year design life expectation. This article focuses on the challenges of this emerging subsea optical industry and current research and development trends for subsea optical hardware, including the creation and maintenance of a subsea materials database for the development of new long life performance subsea products. Reliability engineering, from start to completion of new product development and technology enhancement, is the key to verifying solid engineering through science.

BACKGROUND

Deepwater oil & gas production field systems are experiencing ever-increasing levels of complexity as the fields cover larger ocean floor surface areas, enter deeper waters, and strive for increased percentage levels of oil and gas harvested to improve the economics of production. In addition, momentum on these new oil fields is moving towards even longer performance life expectations, pushing as high as 40 years. These combined complexities are, in turn, driving a surge in the requirements to design equally large health monitoring and management systems using a network of sensors to collect and report data at record levels. The need for greater bandwidth and faster, more reliable data transmission translates well to the use of fiber optical data transmission systems.

This paper will highlight various technology challenges already met by optical products and identify technology gaps that offer areas for further innovation. Specifically, the optical fiber attributes of EMI-immunity, long step-out distance, and long-term performance with increased bandwidth and transmission speed.

CHALLENGES AND EMERGING TECHNOLOGY

EMI Immunity

Enhanced oil recovery initiatives and equipment aimed at increasing product recovery percentages focus primarily on boosting and pumping equipment and systems on the ocean floor that introduce high power transmission at levels not seen just a decade earlier. The case for using fiber optic data transmission networks strengthens in this environment as a byproduct of the inherent EMI immunity of fiber optic transmission.

Subsea pumps that support enhanced recovery of reservoir assets are a key technology for the growing trend of subsea processing. Pump lifetime performance is of great interest to operators, so real-time monitoring of the health of the pump via internal sensors is an attractive solution. For pumps incorporating a large number of sensors, the problem of EMI prohibits the use of electrical sensing in many places.

Electromagnetic waves oscillating in the radio frequency range propagate from pump motors. These waves often interfere with electrical communication of electrical sensing systems, significantly reducing the signal-to-noise ratio and, ultimately, increasing the bit error rate of digital systems also operating in the radio frequency range. Optical fiber offers an attractive mitigation because the optical waves guided within fiber oscillate at frequencies in the hundreds of terahertz, far beyond the reach of the EM noise from the pump motor. Therefore, optical sensors are preferred for investigating vibrational modes of the turbines inside of pump. Analysis of this vibrational data allows predictions of failure modes and pump lifetime.

As on Shell´s Parque das Conchas (BC-10), an optical connector or penetration must separate the fluids within the pump from the seawater outside, while providing a continuous optical throughput for the sensor data.

Lower Back Reflection

Optical sensing also finds a home in Life of Field Seismic (LoFS) applications. Fixed, permanent 4D seismic survey systems demonstrate value by delivering more highly accurate data used to analyze the health and life of a field. Often, a seismic interrogation pulse is injected into the earth and the reflected seismic waves are coupled into sensors on the seafloor. Fiber Bragg Gratings (FBGs) offer a unique way to perform this measurement. A broadband optical signal is launched into the fiber from the platform, and the FBG, based on Bragg’s law, reflects a certain slice of the optical spectrum when the fiber is at rest. With these FBGs laid strategically, as on Petrobras Jubarte field, strain induced by the seismic reflections can alter the reflected spectrum and this wavelength shift can be interpreted, eventually producing information about the structure and health of the field. Optical wet-mate connectors provide a configurable, repairable method of linking optical sensor arrays to each other and back to shore.

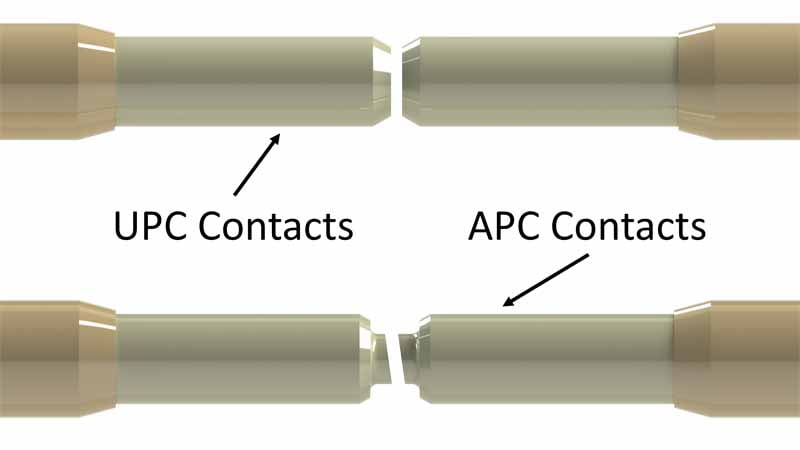

Legacy optical connectors use an Ultra Physical Contact (UPC) polish for the optical end face, resulting in a connector-level return loss of >30 dB. In order to ensure that the FBGs in LoFS systems have adequate bandwidth, Fresnel reflections must be reduced at the optical interface and Angled Physical Contact (APC) polished end faces must be used, as shown in Figure 1. While UPC end faces employ a non-angled polish, the APC end face geometry has a polish angle of 8°. This contact angle of 8° between the two optical end faces results in a wet-mate connector return loss typically >45 dB, which offers sufficient bandwidth for most optical LoFS systems.

Figure 1. Photo rendered fiber optic contact comparison.

Increased Channel Count

The increasing number of sensing and data communication channels has reasonably increased the number of required optical communications channels for a given subsea system. Although multiplexing technologies have been introduced, many oil & gas operators have expressed the desire for redundancy via separate dedicated optical fibers, resulting in an increased number of optical fibers per subsea optical connector. Whereas eight optical fibers were previously the standard for wet-mate optical connectors, 12-fiber and even 24-fiber solutions are now desired to take advantage of all available fibers from the subsea umbilical. To meet these demands, wet-mate connector manufacturers may be able to build on historical designs and increase the channel count. However, in many instances, new optical connectors that incorporate new sealing and actuation technologies must be designed to meet these increased channel count demands.

Electrical/Optical Media Conversion for Long Step-Outs

Along with higher channel counts, longer step-outs have increased the need for subsea fiber optics. Long step-outs prove challenging for electrical cables because of excessive voltage drop. In contrast, optical fiber possesses extremely low loss over long distances. Commonly, subsea hardware vendors incorporate electrical/optical media converters into electronics modules, and the long distance is spanned by pressure-balanced oil-field jumpers with optical flying leads at either end or a long span of optical cable terminated to optical flying leads at each end. However, due to developments in circuit boards and subsea electronics packaging, media converters can now be embedded in the flying leads, reducing the complication of the subsea control modules and providing unique architectural flexibility. A flying lead incorporating electrical to optical conversion is shown in Figure 2. Qualification of new packaged subsea electronics often follows industry specifications originally intended for electronics modules, such as ISO 13628-6.

Figure 2. Flying lead incorporating electrical to optical conversion.

Downhole Challenges

Due to the availability of powerful optical interrogation techniques such as Distributed Temperature Sensing (DTS) and Distributed Acoustic Sensing (DAS), downhole optical sensing continues to increase in popularity. Sensors based on fiber backscatter, discrete gratings, and more exotic optical techniques are used to record temperature, pressure, moisture content, strain, and other well characteristics. As these technologies mature and more optical sensors are deployed subsea, a technology gap exists in the optical wet-mate connector to transfer data in and out of the downhole environment. Such an optical feedthrough may take advantage of technologies like high-temperature epoxies, high-temperature thermoplastics, and elastomers. More extreme pressure and temperatures require the removal of epoxies altogether, as well as the use of metal seals and new, not yet developed materials. The 30-year performance of these materials must then be proven in the service conditions.

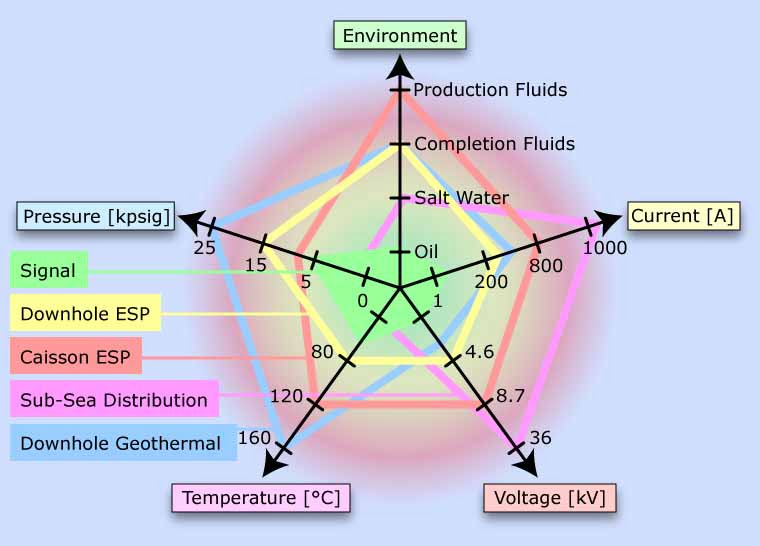

Figure 3. Stress combinations for electrical connectors in various subsea applications.

Qualified Subsea Performance Material Database

Originally developed to investigate new materials for the control of electric fields for subsea power interconnects, the Teledyne Oil & Gas Materials database, in partnership with Teledyne Scientific, is set to provide that valuable material data. Over 186 materials have been tested so far, resulting in over 23,556 completed analyses. The importance of multi-stress testing is shown in Figure 3, where different stress combinations are associated with different subsea power applications.

While conventional test methodologies previously encompassed separate pressure, thermal, or fluid compatibility tests and multi-stress testing, integrating all stressors into a single test demonstrates the true performance of materials during use as they produce the synergistic effects of combined stresses. This method of accelerated aging enables the prediction of end-of-life performance for the development of new, robust elastomers, thermoplastics, and ceramic materials. For example, data on thermoplastic compatibility with operator-specified production fluids while at high temperatures and in-well pressure will support decision-making during the development of the optical feedthrough system (OFS).

The Importance of Reliability

Reliability of the optical products is the cornerstone of addressing these challenges subsea. A well-designed, deployed, and accountable reliability program takes a proactive approach to product development and improvement through the use of various reliability tools. Examples of key tools in the reliability program are the Accelerated Life Test (ALT) implemented within the TOG materials database and the Failure Modes Effects and Criticality Analysis (FMECA). Through Design FMECAs, Teledyne has examined each part in its wet-mate fiber optic connector to determine likely failure modes and understand how each failure mode will affect the functionality of the connector. Similarly, the Process FMECA examines each step in the manufacturing process to look for potential process errors and their effects. By ranking the severity, likelihood of occurrence, and detectability of each failure mode and then combining these rankings, the highest risk items in the design and manufacturing of the wet-mate fiber optic connector have been identified and preventative actions taken to ensure that these failure modes are mitigated. Continuous revisiting of the FMECAs during yearly reviews of field data forms a feedback loop of continuous improvement that has led to the ever increasing reliability of these connectors.

SUMMARY & CONCLUSION

Recent fluctuations and a downturn in the price of crude oil supports development and deployment of even more innovative new technologies aimed to increase oil recovery percentages in new and existing subsea oil production fields. Tremendous investments in time and currency are made towards building these installations, and economies of increased levels of recovery are even more compelling. It is apparent that the complexities of the subsea fields will continue to rise and the need for more accurate and higher densities of sensors to understand and determine field health management and life of field decisions will follow. The introduction of new and more prevalent high-power equipment subsea and the larger step-out and transmission distances will demand fiber optic systems and optical transmission for long-life, high-reliability systems with even more channels and more redundancy than we can forecast today. It will be up to system designers and suppliers to keep pace in order to drive these production economies for the continued health of the energy sector, independent of oil pricing.