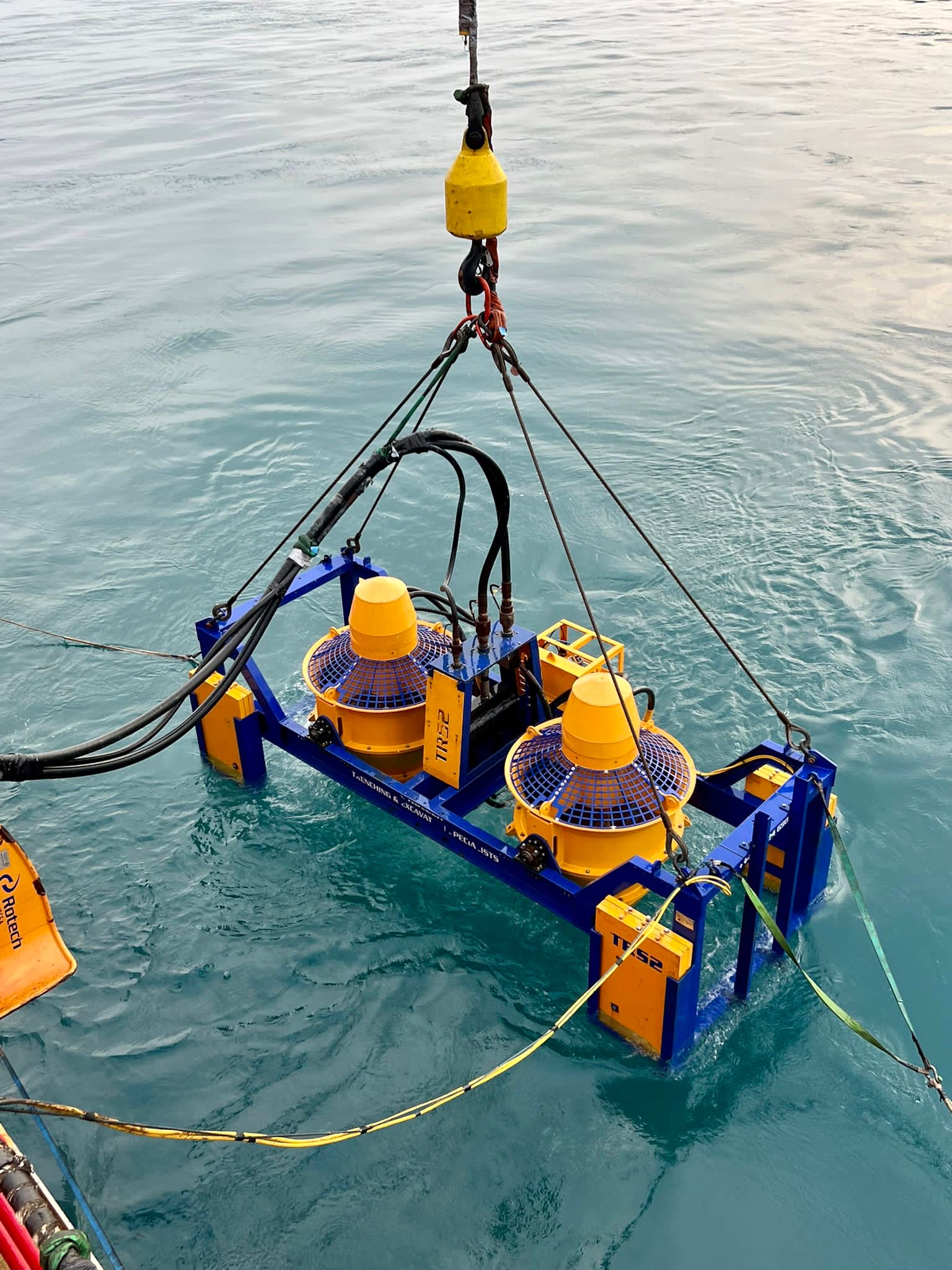

The leading provider of Controlled Flow Excavation (CFE) tools mobilized its TRS2 state-of-the-art CFE spread of equipment at short notice to carry out a vital cable burial scope in varying seabed conditions, ranging from very sandy SILT to silty sand with the potential for clay, cemented sands, and calcarenite.

Base Scope

Operating in water depths of between 2-11.5m, the TRS2 completed what would become a six-part project with a trenching speed of 1-4 m/min at the request of the client. The original base scope saw Rotech bury 3 x 66v 180mm cables – measuring 1.1km – to varying depths up to a maximum of 3m DoL. Rotech’s scope of work included excavating areas with pockmarks/craters noted from approximately KP 1.100 through KP 2.10. A total of 4 passes were completed, and a trench depth of 2.12 to 3.4m was achieved in very hard layers of seabed.

Extended Scope 1

Upon completion of the base scope the client requested further assistance on five more sections of cable. Extended Scope 1 saw the Aberdeen-based jet trenching specialist bury 3 x 66kv cables (measuring 6km) to varying depths up to a maximum of 3m DoL with areas excavated from approximately KP4.50 through KP10.50.

A total of 4 passes were completed, and a trench depth of 2.1 to 3.4m was achieved. Very hard layers were found for most of the cable route. A soft section was located from KP4.71 to KP6.07. The target depth of 3m was achieved in this area. In the more challenging areas where hard soils were located the achieved depth of 2.1m was accepted by the client. Rotech advised that 3m depth could be achieved in these areas with further passes if necessary.

Image credit: Rotech Subsea

Image credit: Rotech Subsea

Extended Scope 2

Extended Scope 2 was in the deep water section of the project, with Rotech burying the 3 x 66kv cables (length 1.12km) to varying depths up to 5 m DoL in the following section. On this Route section areas were excavated from approximately KP11.620 through to KP10.50. A total of 6 passes were completed, and a trench depth of 4m to 6.5m was achieved. Mostly soft soils were located in this section.

Extended Scope 3

Extended Scope 3 saw Rotech deliver remedial burial works on 500m in small sections on cables 1,2,3 from KP3.50 to KP3.00. A total of 4 passes were completed, and a trench depth of 2.00 m to 3.00 m was achieved. Soils were a mix of both hard and soft spots.

Extended Scope 4

Extended Scope 4 saw remedial trenching works executed on areas of cable 1 that were previously buried by the client’s tracked trencher. Remedial works were required in 12 locations totalling approximately 1.1km (3 passes were required on x9 of the 12 sections, 4 passes were required on x2 of the 12 sections, 5 passes were required on x1 of the 12 sections). Trench depth of 2.2 m to 2.9 m was achieved, Very hard soils were located in these sections.

Extended Scope 5

Extended Scope 5 saw Rotech carrying out 3 passes of remedial trenching in 28 sections of the cable route to reduce the number of concrete mattresses that would need to be installed by the client. A total of 3 passes were completed, and a trench depth of 2.2 to 2.7m was achieved. Very hard layers were found for most of the cable route.

Image credit: Rotech Subsea

Image credit: Rotech Subsea

Speaking about the IRM works, Rotech Subsea Director of Subsea, Stephen Cochrane, commented: “This extended project in what has become familiar territory for us was another extremely successful deployment even though it posed some tough challenges. The client was very happy with the outcome and were very impressed with the power of our TRS2 CFE jet trencher and the capabilities of our team of project engineers.

“Having mobilized at short notice, we also facilitated multiple additional scopes of work seamlessly and the client later advised that we had managed to save them from laying over 200 concrete mattresses due to the success of the trenching completed in this scope.”

Rotech Subsea’s research, development and engineering team has created a suite of 18 sector-leading non-contact CFE, Suspended Jet Trenching tools in-house at its Aberdeen HQ. With enhanced capabilities, Rotech Subsea’s CFE suite of tools is firmly established as the method of choice for offshore wind farm cable trenching and excavation in Europe and beyond.